©2017 Comnat Inc.

Primary Containment Lining Systems

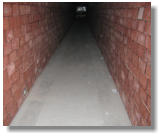

Primary containment lining systems used to continuously hold

harsh process or waste chemicals most likely require more that

just a simple hi build coating system. They normally need to be

more robust and have enough integrity to not only hold up to

the chemical service but also under adverse conditions such as

abrasion and thermal cycles over many years.

Primary containment linings protect not only the containment

structure itself but more importantly the surrounding

environment and the health and safety of employees.

Products ranging from heavy duty spray applied mortars, fabric

and fiberglass flake reinforced systems, thermoplastics,

membrane, acid brick and mortar are among the selection of

linings that may be appropriate for the service application such

as tanks, trenches, sumps, pits or process vessels.

Linings that initially appear "economical" may in fact cost much

more if they require constant maintenance or fail prematurely.

We provide the capability to spark test most of our lining

systems to certify the lining's integrity after the initial installation

or to verify it later.

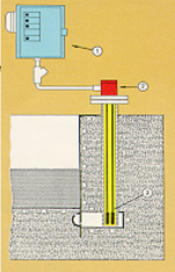

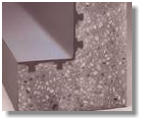

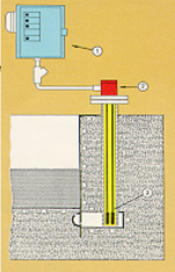

Anchor-Lok is mechanically anchored

in concrete leaving a hairline

interstitial space that allows for leak

detection monitoring.

(See diagram below)

Anchor-Lok is a pre-engineered, pre-

fabricated thermoplastic lining assembly

that incorporates PP, HDPE, PVC, and PVDF

sheet, a patented conical anchor design,

weld rod, and metal tape for spark testing to

create a certified leakproof "system" that will

provide maintenance free service for 40

years or more. Anchor-Lok Linings also

offer leak detection capabiliy.

Wire Coil Pickle Tank Rehabilitation Project

Shop and field welds are

spark tested to certify

pinhole free integrity of the

liner prior to being placed

into service.

Chempruf systems are both

primary and secondary

containment linings from

Atlas Minerals & Chemicals,

Inc. They are typically either

a high build epoxy,

polyester, furan or vinyl

ester resin that include

fiberglass flakes or a multi -

layer mortar and fiberglass

matte reinforcement

system.

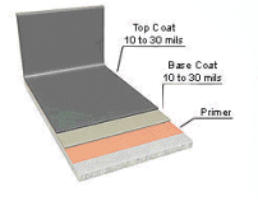

Coating System

The Fiberglass flakes in the coating and trowel systems eliminate permeation through the lining and the add a

considerable tensile strength, abrasion and impact resistance.

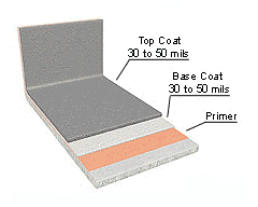

Fiberglass fabric reinforced systems are typically 1/8" thick and are trowel applied in layers of 60 to 90 mil basecoat

and topcoat with resin saturated fiberglass fabric sandwiched in between. This is a hand layup system that is similar

that used in fabricating contact molded fiberglass tanks and boats.

Trowell System

Mortar & Fabric System

The Fiberglass flakes in the coating and trowel

systems eliminate permeation through the lining

and the add a considerable tensile strength,

abrasion and impact resistance.

Fiberglass fabric reinforced systems are

typically 1/8" thick and are trowel applied in

layers of 60 to 90 mil basecoat and topcoat with

resin saturated fiberglass fabric sandwiched in

between. This is a hand layup system that is

similar that used in fabricating contact molded

fiberglass tanks and boats.

©2017 Comnat Inc.

Primary Containment Lining Systems

Primary containment lining systems used to

continuously hold harsh process or waste

chemicals most likely require more that just a

simple hi build coating system. They normally need

to be more robust and have enough integrity to not

only hold up to the chemical service but also under

adverse conditions such as abrasion and thermal

cycles over many years.

Primary containment linings protect not only the

containment structure itself but more importantly

the surrounding environment and the health and

safety of employees.

Products ranging from heavy duty spray applied

mortars, fabric and fiberglass flake reinforced

systems, thermoplastics, membrane, acid brick and

mortar are among the selection of linings that may

be appropriate for the service application such as

tanks, trenches, sumps, pits or process vessels.

Linings that initially appear "economical" may in

fact cost much more if they require constant

maintenance or fail prematurely. We provide the

capability to spark test most of our lining systems

to certify the lining's integrity after the initial

installation or to verify it later.

Anchor-Lok is mechanically anchored

in concrete leaving a hairline

interstitial space that allows for leak

detection monitoring.

(See diagram below)

Anchor-Lok is a pre-engineered, pre-

fabricated thermoplastic lining assembly

that incorporates PP, HDPE, PVC, and PVDF

sheet, a patented conical anchor design,

weld rod, and metal tape for spark testing to

create a certified leakproof "system" that will

provide maintenance free service for 40

years or more. Anchor-Lok Linings also

offer leak detection capabiliy.

Wire Coil Pickle Tank Rehabilitation Project

Shop and field welds are

spark tested to certify

pinhole free integrity of the

liner prior to being placed

into service.

Chempruf systems are both

primary and secondary

containment linings from

Atlas Minerals & Chemicals,

Inc. They are typically either

a high build epoxy,

polyester, furan or vinyl

ester resin that include

fiberglass flakes or a multi -

layer mortar and fiberglass

matte reinforcement

system.

Coating System

The Fiberglass flakes in the coating and

trowel systems eliminate permeation through

the lining and the add a considerable tensile

strength, abrasion and impact resistance.

Fiberglass fabric reinforced systems are

typically 1/8" thick and are trowel applied in

layers of 60 to 90 mil basecoat and topcoat

with resin saturated fiberglass fabric

sandwiched in between. This is a hand layup

system that is similar that used in fabricating

contact molded fiberglass tanks and boats.

Trowell System

Mortar & Fabric System

- Resinous Floor & Wall Coatings

- Epoxy & Urethane Floor Overlays

- Concrete Mending & Polyurea Joint Sealants

- Rapid Joint Filler

- Polymer Concrete & Machinery Grout

- Tile & Brick Food Plant Floors

- Secondary Containment Lining Systems

- Primary Containment Lining Systems

- Liquid Stainless Steel & High Performance Paints

- Fiberglass Grating Platforms & Walkways

- Home

- About

- Line Card

- Contact

- Product Overview

- Resinous Floor & Wall Coatings

- Epoxy & Urethane Floor Overlays

- Concrete Mending & Polyurea Joint Sealants

- Rapid Joint Filler

- Polymer Concrete & Machinery Grout

- Tile & Brick Food Plant Floors

- Secondary Containment Lining Systems

- Primary Containment Lining Systems

- Liquid Stainless Steel & High Performance Paints

- Fiberglass Grating Platforms & Walkways

- NEWS