©2017 Comnat Inc.

Secondary Containment Lining Systems

1.

Keep hazardous materials from contaminating the surrounding environment as mandated by state

DEP and federal EPA regulations

2.

Protect expensive structural and process investments with minimal required maintenance, repairs or

replacement.

Federal and state EPA/DEP requirements for

secondary containment mandate the containment

must hold any spills, catastrophic or otherwise, from

leaking into the surrounding environment for a

period of at least 72 hours.

There are a number of secondary containment

coating or lining selections that can be made

depending on the volatility of product or chemicals

being safeguarded. They can range from a

corrosion resistant coating to fabric reinforced

lining to thermoplastics. Design and selection

considerations besides catastrophic spill

containment are splash & spill protection due to

occasional equipment leaks, potential physical

abuse, thermal extremes or cycling, vehicular or

pedestrian

traffic activity and safety as well as economic and

budgetary constraints.

Rezklad Spray Applied Coatings

Rezklad 135S is a sprayed system that quickly

applies a 1/8" (125 mil) textured non-slip

novolac epoxy coating on horizontal, vertical

and overhead areas. The 135S and the Rezklad

125S-AR (Abrasion Resistant) system are widely

used as linings in the water/wastewater

treatment industry, The material is designed to

spray through a carrousel spray hopper that

forced the material to a wand where 60psi

airstream atomizes the material into a spray

pattern.

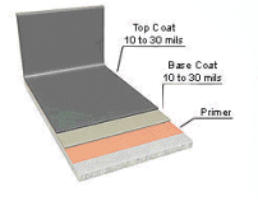

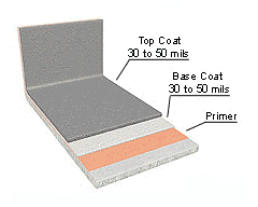

Chempruf Lining Systems

Chempruf systems from Atlas Minerals & Chemicals, Inc. are both primary and secondary containment

lining. The product line ranges from a high build fiberglass flake reinforced 20-30 mil coatings to a 600-

100 mil trowell applied mortar system to a multi-layer mortar and a fiberglass fabric reinforced laminate

system. These systems offer the selection of epoxy, furan, polyester and vinyl ester binder resins..

Fiberglass flake in the coating and trowel systems prevent permeation of liquids through the lining and

the add a considerable tensile strength and abrasion resistance. The resin selection and the fiberglass

filler make the material chemically insert to a wide array of corrosive materials.

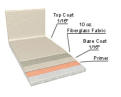

Fiberglass fabric reinforced systems are typically 1/8" thick systems that are trowel applied in 60 mil

layers of a basecoat and topcoat with resin saturated 10 ounce fiberglass fabric in between. This is

known as a "contact molded" or "hand layup" system similar to the technique used in fabricating

fiberglass tanks and boats.

Fiberglass fabric reinforced systems are typically 1/8"

thick systems that are trowel applied in 60 mil layers of a

basecoat and topcoat with resin saturated 10 ounce

fiberglass fabric in between. This is known as a "contact

molded" or "hand layup" system similar to the technique

used in fabricating fiberglass tanks and boats.

©2017 Comnat Inc.

Secondary Containment Lining Systems

1.

Keep hazardous materials from contaminating

the surrounding environment as mandated by

state DEP and federal EPA regulations

2.

Protect expensive structural and process

investments with minimal required

maintenance, repairs or replacement.

Federal and state EPA/DEP requirements for

secondary containment mandate the containment

must hold any spills, catastrophic or otherwise, from

leaking into the surrounding environment for a

period of at least 72 hours.

There are a number of secondary containment

coating or lining selections that can be made

depending on the volatility of product or chemicals

being safeguarded. They can range from a

corrosion resistant coating to fabric reinforced

lining to thermoplastics. Design and selection

considerations besides catastrophic spill

containment are splash & spill protection due to

occasional equipment leaks, potential physical

abuse, thermal extremes or cycling, vehicular or

pedestrian

traffic activity and safety as well as economic and

budgetary constraints.

Rezklad Spray Applied Coatings

Rezklad 135S is a sprayed system that quickly

applies a 1/8" (125 mil) textured non-slip

novolac epoxy coating on horizontal, vertical

and overhead areas. The 135S and the Rezklad

125S-AR (Abrasion Resistant) system are widely

used as linings in the water/wastewater

treatment industry, The material is designed to

spray through a carrousel spray hopper that

forced the material to a wand where 60psi

airstream atomizes the material into a spray

pattern.

Chempruf Lining Systems

Chempruf systems from Atlas Minerals &

Chemicals, Inc. are both primary and

secondary containment lining. The

product line ranges from a high build

fiberglass flake reinforced 20-30 mil

coatings to a 600-100 mil trowell applied

mortar system to a multi-layer mortar

and a fiberglass fabric reinforced

laminate system. These systems offer

the selection of epoxy, furan, polyester

and vinyl ester binder resins..

Fiberglass flake in the coating and trowel systems

prevent permeation of liquids through the lining and

the add a considerable tensile strength and

abrasion resistance. The resin selection and the

fiberglass filler make the material chemically insert

to a wide array of corrosive materials.

Fiberglass fabric reinforced systems are typically

1/8" thick systems that are trowel applied in 60 mil

layers of a basecoat and topcoat with resin

saturated 10 ounce fiberglass fabric in between.

This is known as a "contact molded" or "hand layup"

system similar to the technique used in fabricating

fiberglass tanks and boats.

- Resinous Floor & Wall Coatings

- Epoxy & Urethane Floor Overlays

- Concrete Mending & Polyurea Joint Sealants

- Rapid Joint Filler

- Polymer Concrete & Machinery Grout

- Tile & Brick Food Plant Floors

- Secondary Containment Lining Systems

- Primary Containment Lining Systems

- Liquid Stainless Steel & High Performance Paints

- Fiberglass Grating Platforms & Walkways

- Home

- About

- Line Card

- Contact

- Product Overview

- Resinous Floor & Wall Coatings

- Epoxy & Urethane Floor Overlays

- Concrete Mending & Polyurea Joint Sealants

- Rapid Joint Filler

- Polymer Concrete & Machinery Grout

- Tile & Brick Food Plant Floors

- Secondary Containment Lining Systems

- Primary Containment Lining Systems

- Liquid Stainless Steel & High Performance Paints

- Fiberglass Grating Platforms & Walkways

- NEWS